Inconel Welding Applications

CLADDING WITH INCONEL CAN BE A SIMPLE WELD JOB WHEN YOU USE THE RIGHT WELD PROCESS.

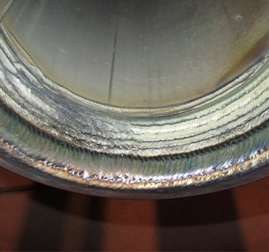

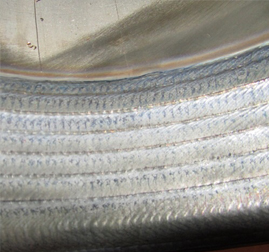

You have to manually clad the end of a pipe ID with Inconel. You could use Pulsed MIG as shown on the LEFT or use TIP TIG as shown on the RIGHT.

TIP TIG inconel 800 pipe welded with inconel 82 wire on 10 inch pipe 3/4 wall.

(welded with lowest possible weld heat).

The TIP TIG weld cycle time for the inconel pipe was 40 – 50 minutes and would be reduced further if reduced Vee groove preps were utilized. The customer used to take around 4 hrs with regular TIG. When your weld process can weld a complex incoloy pipe and make the welds look simple, that’s a process that should be given consideration. With TIP TIG, no brushing, no grinding, no spatter, no weld rework, no feeding a wire, no foot control, less skills. Note weld smoke prep machining lubricants.

WATCH THESE VIDEOS